-

Pneumatic Programmable Valve

Pneumatic program control stop valve is the executive component of industrial production process automation, through the signal from industrial controller or controllable signal source, control the opening and closing of the valve to achieve medium of the pipe’s cut-off and conduction so that realizing automatic control & regulation of the parameters such as flow, pressure, temperature and ... -

Hydrogen Production by Water Electrolysis

Hydrogen production by water electrolysis has the advantages of flexible application site, high product purity, large operation flexibility, simple equipment and high degree of automation, and is widely used in industrial, commercial and civil fields. In response to the country’s low-carbon and green energy, hydrogen production by water electrolysis is widely deployed in places for green ... -

Hydrogen Production by Steam Methane Reforming

The steam methane reforming (SMR) technology is used for the gas preparation, where the natural gas is the feedstock. Our unique patented technology can greatly reduce equipment investment and reduce raw material consumption by 1/3 • Mature technology and safe operation. • Simple operation and high automation. • Low operating costs and high returns After pressurized desulfurization, natural gas... -

Hydrogen Production by Methanol Reforming

Hydrogen production by methanol-reforming is the best technology choice for clients with no source of hydrogen production raw materials. The raw materials are easy to obtain, easy to transport and store, the price is stable. With the advantages of low investment, no pollution, and low production cost, hydrogen generation by methanol is the best method for hydrogen production and has strong mark... -

Hydrogen Purification by Pressure Swing Adsorption

PSA is short for Pressure Swing Adsorption, a technology widely used for gas separation. According to the different characteristics and affinity for an adsorbent material of each component and use it to separate them under pressure. Pressure Swing Adsorption (PSA) technology is widely used in the field of industrial gas separation because of its high purity, high flexibility, simple equipment,... -

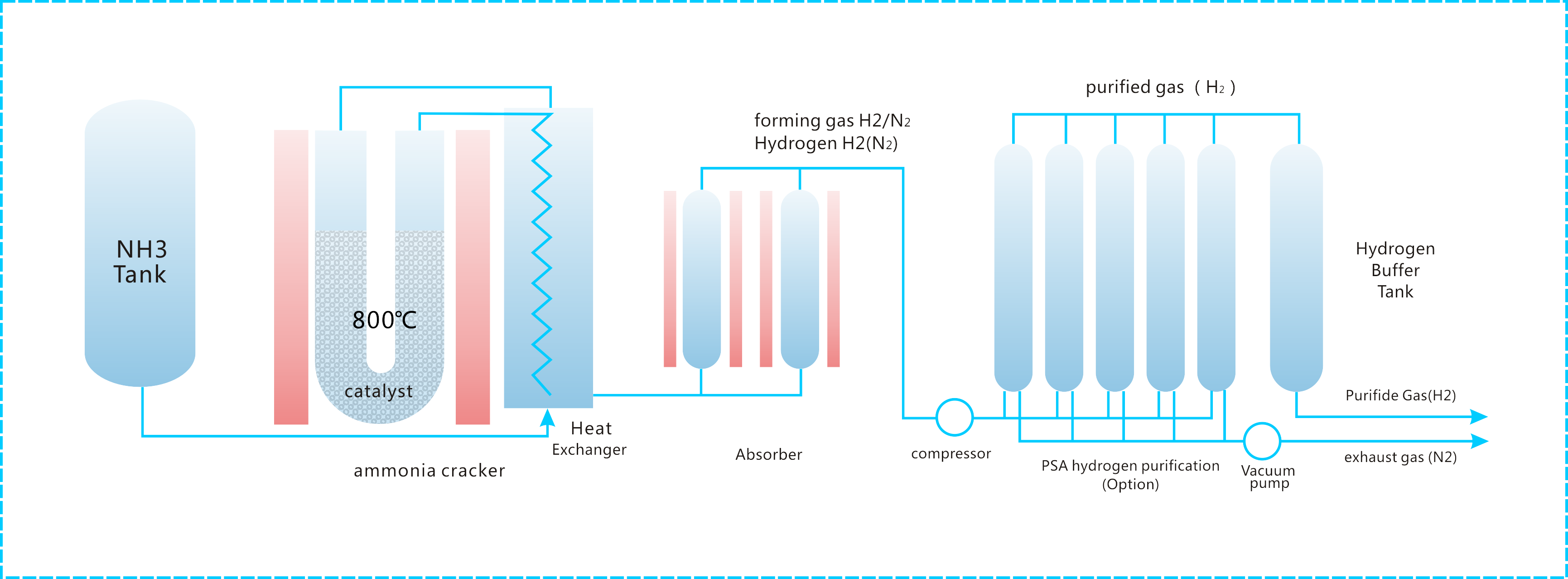

Hydrogen Production by Ammonia Cracking

An ammonia cracker is used to generate the cracking gas which is consisted of hydrogen ant nitrogen at mole ratio of 3:1. The absorber cleans the forming gas from remaining ammonia and moisture. Then a PSA unit is applied to separate hydrogen from nitrogen as optional. The NH3 is coming from bottles or from an ammonia tank. The ammonia gas is pre-heated in a heat exchanger and vaporizer and the... -

Long-term uninterrupted Power Supply System

Ally Hi-tech’s hydrogen backup power system is a compact machine integrated with hydrogen generation unit, PSA unit and power generation unit. Using methanol water liquor as feedstock, hydrogen backup power system can realize long time power supply as long as there is enough methanol liquor. No matter for islets, desert, emergency or for military uses, this hydrogen power system can provide wit... -

Integrated Hydrogen Production and Hydrogen Refueling Station

Utilize the existing mature methanol supply system, natural gas pipeline network, CNG and LNG refueling stations and other facilities to build or expand the integrated hydrogen production and hydrogen refueling station. Through hydrogen production and refueling in the station, the hydrogen transportation links are reduced and the cost of hydrogen production, storage and transportation is reduce... -

Biogas Purification and Refinery Plant

Biogas is a kind of environment-friendly, clean, and cheap combustible gas produced by microorganisms in anaerobic environments, such as livestock manure, agricultural waste, industrial organic waste, domestic sewage, and municipal solid waste. The main components are methane, carbon dioxide, and hydrogen sulfide. Biogas is mainly purified and purified for city gas, vehicle fuel, and hydrogen p... -

CO gas Purification and Refinery Plant

Pressure swing adsorption (PSA) process was used to purify CO from mixed gas containing CO, H2, CH4, carbon dioxide, CO2, and other components. The raw gas enters a PSA unit to adsorb and remove CO2, water, and trace sulfur. The purified gas after decarbonization enters the two-stage PSA device to remove impurities such as H2, N2, and CH4, and the adsorbed CO is exported as a product through va... -

Food Grade CO2 Refinery and Purification Plant

CO2 is the main by-product in the process of hydrogen production, which has high commercial value. The concentration of carbon dioxide in wet decarbonization gas can reach more than 99% (dry gas). Other impurity contents are: water, hydrogen, etc. after purification, it can reach food grade liquid CO2. It can be purified from hydrogen reforming gas from natural gas SMR, methanol cracking gas, l... -

Syngas Purification and Refinery Plant

The removal of H2S and CO2 from syngas is a common gas purification technology. It is applied in the purification of NG, SMR reforming gas, coal gasification, LNG production with coke oven gas, SNG process. MDEA process is adopted to remove H2S and CO2. After purification of syngas, H2S is less than 10mg / nm 3, CO2 is less than 50ppm (LNG process).

Hydrogen Refueling Station

Hydrogen Refueling Station Long-run UPS System

Long-run UPS System Integrated Chemical Plant

Integrated Chemical Plant Core Accessories

Core Accessories