CO gas Purification and Refinery Plant

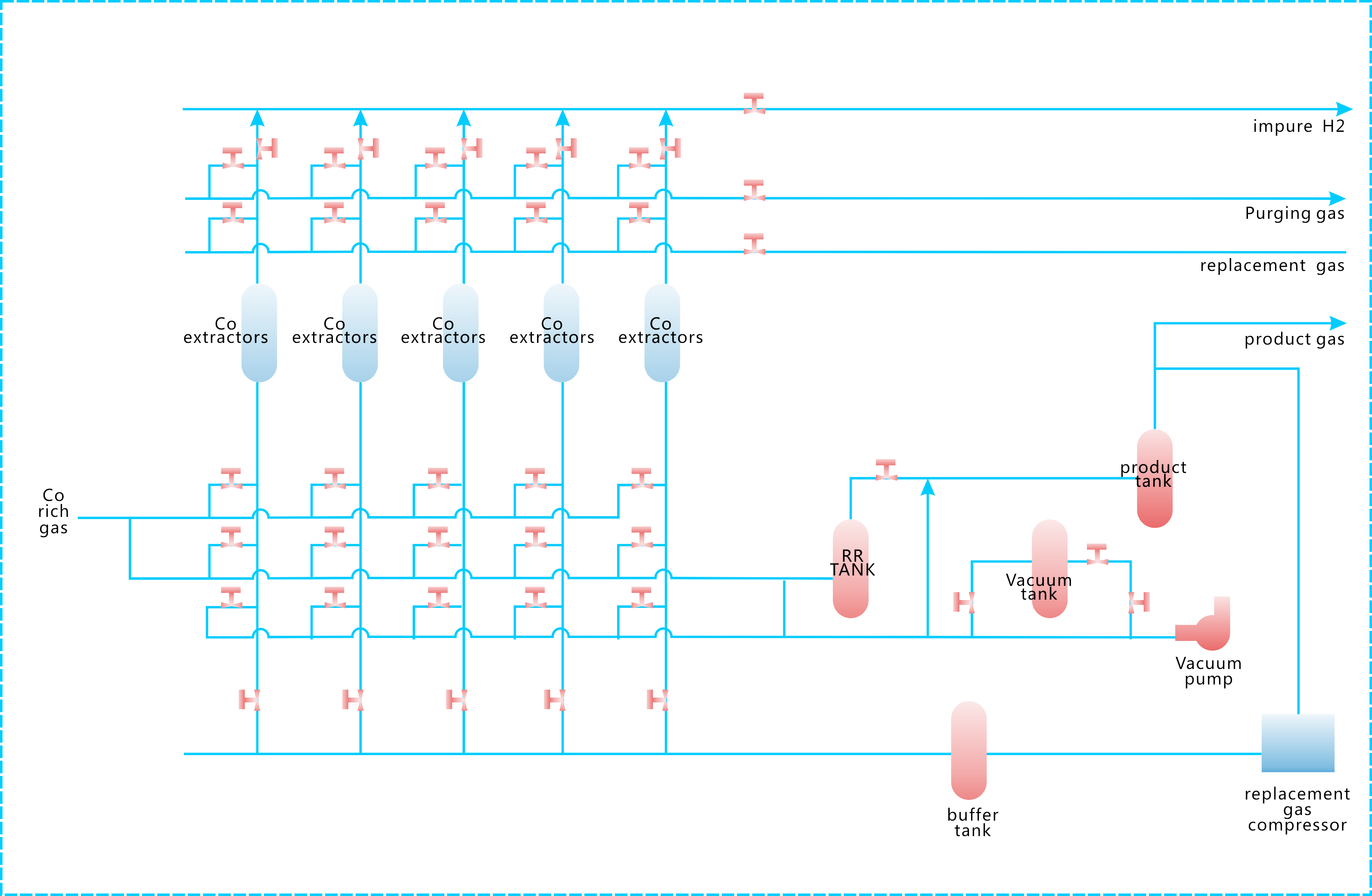

Pressure swing adsorption (PSA) process was used to purify CO from mixed gas containing CO, H2, CH4, carbon dioxide, CO2, and other components. The raw gas enters a PSA unit to adsorb and remove CO2, water, and trace sulfur. The purified gas after decarbonization enters the two-stage PSA device to remove impurities such as H2, N2, and CH4, and the adsorbed CO is exported as a product through vacuum decompression desorption.

CO purification through PSA technology is different from H2 purification in that CO is adsorbed by the PSA system. The adsorbent for purifying CO is developed by Ally Hi-Tech. It has the advantage of large adsorption capacity, high selectivity, simple process, high purity, and high yield.

Technology Characteristics

|

Plant size |

5~3000Nm3/h |

|

Purity |

98~99.5% (v/v) |

|

Pressure |

0.03~1.0MPa(G) |

Applicable Fields

● From water gas and semi water gas.

● From yellow phosphorus tail gas.

● From the tail gas of calcium carbide furnace.

● From methanol cracking gas.

● From blast furnace gas.

● From other sources rich in carbon monoxide.

Characteristics and hazards

Carbon monoxide is a colorless, odorless toxic gas, which has great harm to the human body and the environment. The main sources of carbon monoxide include combustion equipment, automobile exhaust and industrial production. Prolonged exposure to carbon monoxide can cause a range of health problems, such as headaches, nausea, vomiting, chest tightness and other symptoms. Severe cases of poisoning can lead to coma and even death. In addition, carbon monoxide is also closely related to air pollution and the greenhouse effect, and the damage to the atmosphere can not be ignored. In order to protect our bodies and the environment, we should regularly check the emissions of combustion equipment, raise public awareness of environmental protection, and strengthen regulatory measures and regulations to reduce carbon monoxide emissions and create a healthier and cleaner environment.