Integrated Hydrogen Production and Hydrogen Refueling Station

Utilize the existing mature methanol supply system, natural gas pipeline network, CNG and LNG refueling stations and other facilities to build or expand the integrated hydrogen production and hydrogen refueling station. Through hydrogen production and refueling in the station, the hydrogen transportation links are reduced and the cost of hydrogen production, storage and transportation is reduced. The production and processing integration station is the best way to reduce the export hydrogen price of the hydrogen muzzle and realize the transformation of the hydrogen refueling station from commercial demonstration to commercial operation profit model.

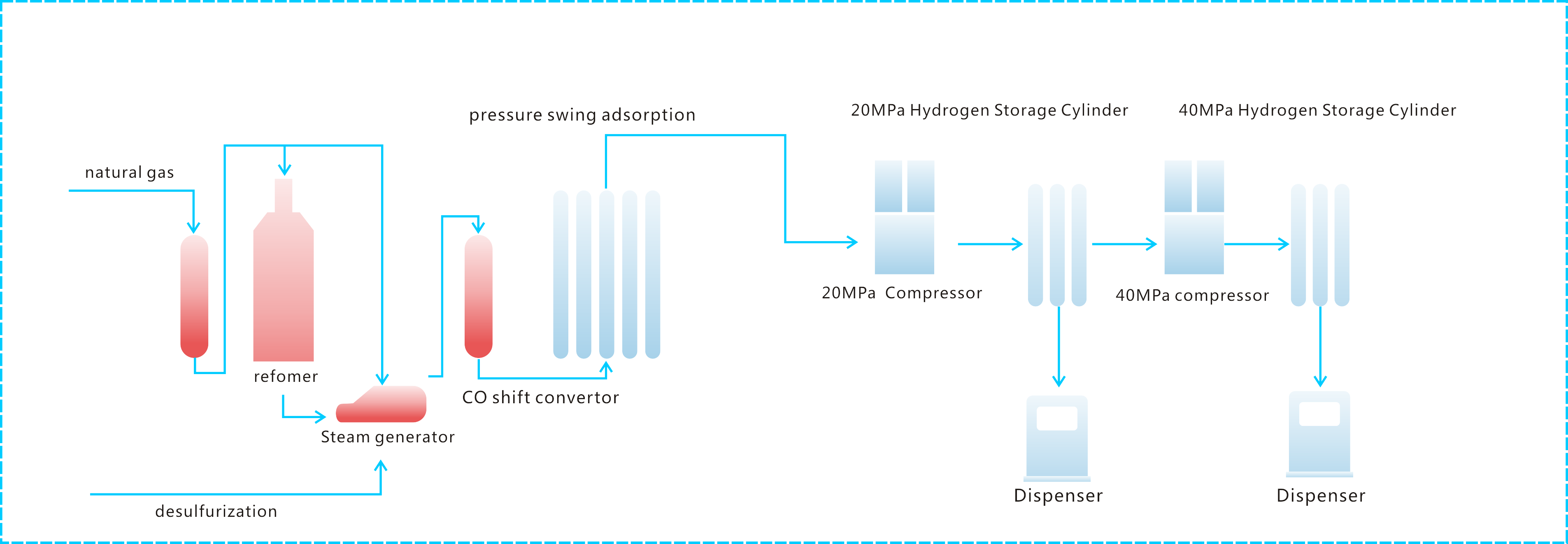

Technical Process

Using purchased methanol or pipeline natural gas, LNG, CNG or municipal water supply to produce hydrogen in the station that meets the hydrogen standards for fuel cells; The product hydrogen is compressed to 20MPa for primary storage, and then pressurized to 45MPa or 90MPa, and then filled into fuel cell vehicles through the hydrogen station filling machine; At the same time, the 20MPa long tube trailer can be filled at the primary storage end to provide hydrogen to other hydrogen stations, which is especially suitable for the establishment of integrated hydrogen production and refueling parent station in the suburbs of the city, and the establishment of hydrogen sub-station in the city center to form a regional comprehensive hydrogen production sub-station.

Flow diagram of integrated hydrogen production and hydrogen refueling station (taking natural gas as an example)

Technology Characteristics

● Unified intelligent control system with high degree of automation

● Large operating flexibility, hydrogen production has standby mode

● Skid design, high integration and small footprint

● Safe & reliable technology

● It is easy to promote and duplicate by reconstruction and expansion of the existing natural gas refueling station.

Technical Parameters

Integrated Station

Hydrogen production, compression, hydrogen storage, hydrogen refueling station and utilities

The integrated station covers an area of 3400m2 — 62×55 m

Among them, hydrogen production:

250Nm³/h is equipped with 500kg/d hydrogen refueling station — 8×10 m (the peripheral beautification is estimated to be 8×12 m)

500Nm³/h is equipped with a 1000kg/d hydrogenation station of — 7×11m (the peripheral beautification of the station is estimated to be 8×12 m)

Safety distance: according to the technical specification 50516-2010 of hydrogen refueling station.

Hydrogen Cost

Cost of hydrogen station port:<30 CNY/kg

Natural gas price: 2.5 CNY/Nm³

System Pressure

Hydrogen production outlet pressure: 2.0MPag

Hydrogen storage pressure: 20MPag or 45MPag

Refueling pressure: 35 or 70MPag