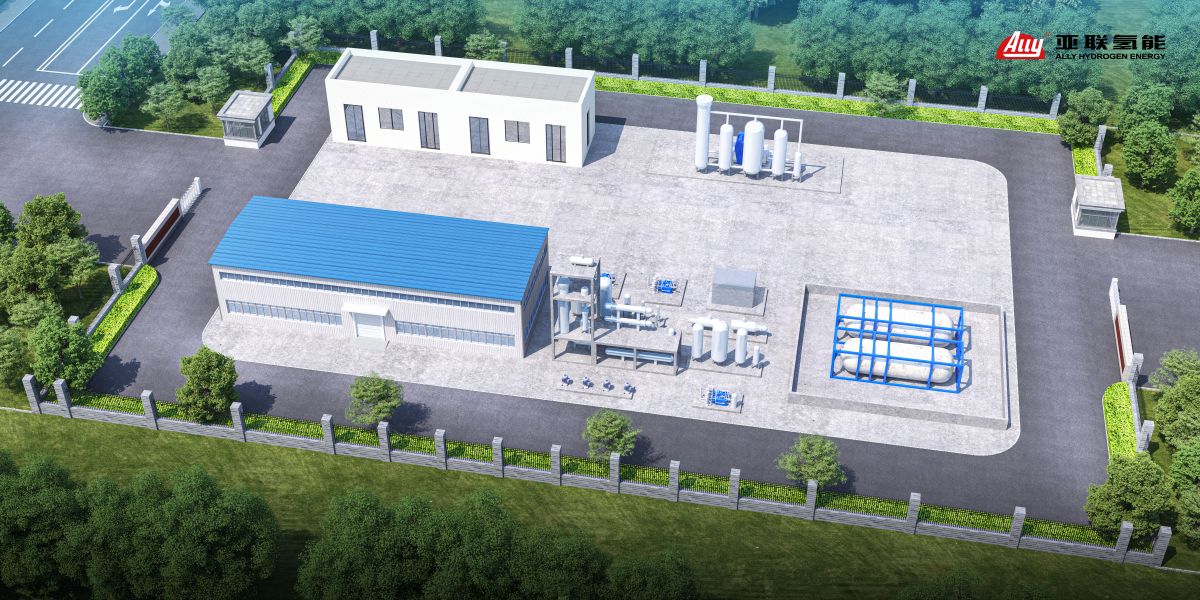

Synthetic Ammonia Refinery Plant

Use natural gas, coke oven gas, acetylene tail gas or other sources containing rich hydrogen as raw materials to build small and medium-sized synthetic ammonia plants. It has the characteristics of short process flow, low investment, low production cost and low discharge of three wastes, and is a production and construction plant that can be vigorously promoted.

Technology Characteristics

● Small investment. The investment of using natural gas as raw material can be reduced by 50% compared with using solid material as raw material.

● Energy saving and full recovery of system heat. The main power equipment can be driven by steam to realize the comprehensive utilization of heat energy.

● Energy saving technologies, such as hydrogen recovery technology, pre-conversion technology, natural gas saturation technology and combustion air preheating technology, are adopted to reduce production costs.

Technical Process

Natural gas is used as raw material to produce certain synthetic gas (mainly composed of H2 and N2) through compression, desulfurization, purification, transformation, hydrogen purification and nitrogen addition. The syngas is further compressed and enters the ammonia synthesis tower to synthesize ammonia under the action of catalyst. After synthesis, the product ammonia is obtained after cooling.

Process Principle

This process is a three-stage process. Firstly, natural gas is used to prepare syngas, then hydrogen is separated by pressure swing adsorption, and then ammonia is synthesized by adding nitrogen.

Main performance indicators

|

Plant Size |

≤ 150MTPD (50000MTPA) |

|

Purity |

99.0~99.90% (v/v), in line with GB536-2017 |

|

Pressure |

Normal Pressure |

Modular Green Ammonia Synthesis

It is produced with green renewable energy, has zero carbon emission in its life cycle, is liquefied at normal temperature and convenient for storage and transportation, and has high hydrogen content, which is known as an important part of the future energy system. Green ammonia will gradually replace traditional energy in energy transportation, chemical raw materials, fertilizers and other aspects to help the whole society reduce carbon emissions.

With modular design idea, standardized production of an ammonia plant can be achieved by standard equipment. Rapid plant construction is the best choice to match renewable energy such as wind and photovoltaic power in the future.

Modular green ammonia synthesis technology adopts low pressure synthesis system and high efficiency synthesis catalyst to achieve high net value. At present, the modular green ammonia synthesis system has three series: 3000t/a, 10000t/a and 20000t/a.

1) The system is highly modular and covers a small area; The modular skid-mounted system is completed in the processing plant, with less on-site construction;

2) The patented technology of Ally Hydrogen Energy Co., Ltd. is adopted to optimize the process, reduce the number of equipment and achieve high equipment integration;

3) Multi-stream high efficiency wounded tube type heat exchange equipment is adopted, which is small in heat exchange equipment, high in heat exchange efficiency and easier to modularize;

4) The new and high-efficiency synthetic ammonia tower reactor has high net value and high internal volume utilization rate;

5) Optimized cyclic compression process makes synthetic ammonia plant have a wide adjustment function;

6) The power consumption of the system is low.