-

Hydrogen Production by Water Electrolysis

Hydrogen production by water electrolysis has the advantages of flexible application site, high product purity, large operation flexibility, simple equipment and high degree of automation, and is widely used in industrial, commercial and civil fields. In response to the country’s low-carbon and green energy, hydrogen production by water electrolysis is widely deployed in places for green ... -

Hydrogen Production by Steam Methane Reforming

The steam methane reforming (SMR) technology is used for the gas preparation, where the natural gas is the feedstock. Our unique patented technology can greatly reduce equipment investment and reduce raw material consumption by 1/3 • Mature technology and safe operation. • Simple operation and high automation. • Low operating costs and high returns After pressurized desulfurization, natural gas... -

Hydrogen Production by Methanol Reforming

Hydrogen production by methanol-reforming is the best technology choice for clients with no source of hydrogen production raw materials. The raw materials are easy to obtain, easy to transport and store, the price is stable. With the advantages of low investment, no pollution, and low production cost, hydrogen generation by methanol is the best method for hydrogen production and has strong mark... -

Hydrogen Purification by Pressure Swing Adsorption

PSA is short for Pressure Swing Adsorption, a technology widely used for gas separation. According to the different characteristics and affinity for an adsorbent material of each component and use it to separate them under pressure. Pressure Swing Adsorption (PSA) technology is widely used in the field of industrial gas separation because of its high purity, high flexibility, simple equipment,... -

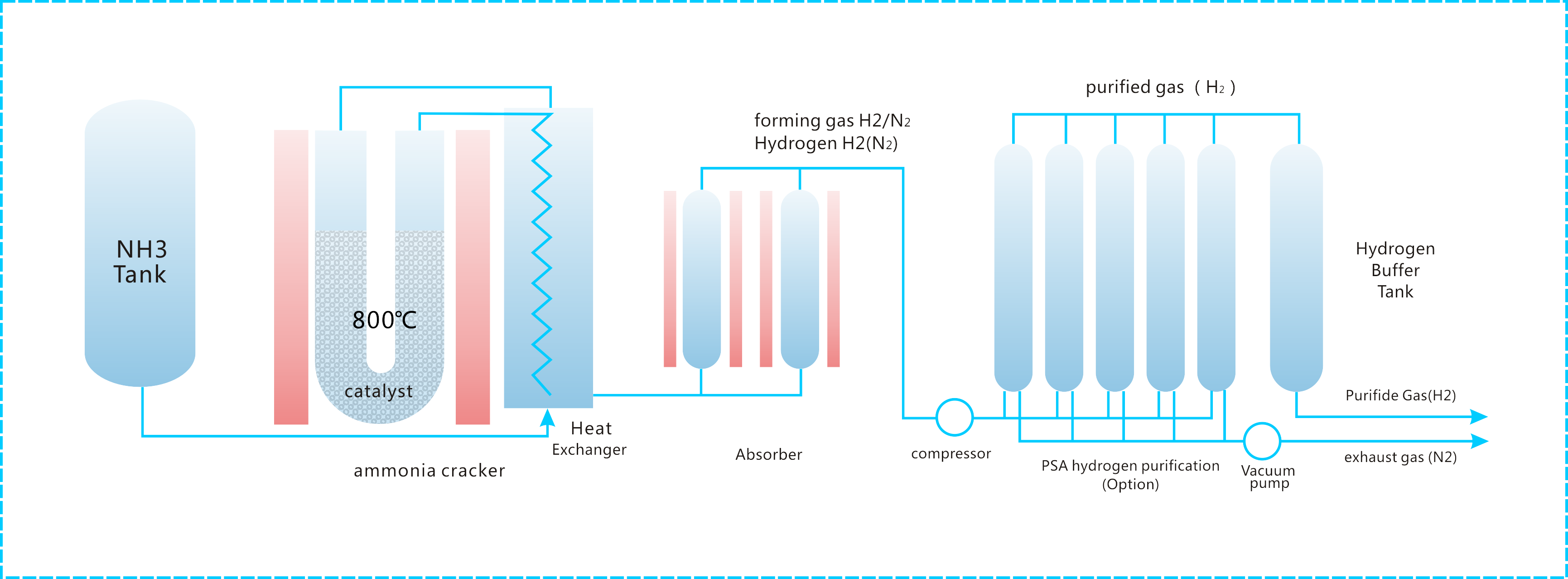

Hydrogen Production by Ammonia Cracking

An ammonia cracker is used to generate the cracking gas which is consisted of hydrogen ant nitrogen at mole ratio of 3:1. The absorber cleans the forming gas from remaining ammonia and moisture. Then a PSA unit is applied to separate hydrogen from nitrogen as optional. The NH3 is coming from bottles or from an ammonia tank. The ammonia gas is pre-heated in a heat exchanger and vaporizer and the...