Hydrogen Purification by Pressure Swing Adsorption

PSA is short for Pressure Swing Adsorption, a technology widely used for gas separation. According to the different characteristics and affinity for an adsorbent material of each component and use it to separate them under pressure.

Pressure Swing Adsorption (PSA) technology is widely used in the field of industrial gas separation because of its high purity, high flexibility, simple equipment, and a high degree of automation. Through years of pressure swing adsorption research and test, we developed a variety of hydrogen-rich gas purification technology and PSA separation and purification technology of carbon monoxide, carbon dioxide, methane, nitrogen, oxygen, and other PSA separation and purification technology, to provide customers with equipment upgrading and transformation services.

Ally Hi-Tech has designed and supplied more than 125 PSA hydrogen plants all over the world. Besides, we have a PSA unit for each methanol or SMR hydrogen production plant as well.

Ally Hi-Tech has supplied more than 125 low-cost hydrogen pressure swing adsorption systems around the world. The capacity of the hydrogen units is from 50 to 50,000Nm3/h. The feedstock can be biogas, coke oven gas, and other hydrogen-rich gas. We have rich experience in the hydrogen purification field and provide our clients with high-quality, low-cost hydrogen production pressure swing adsorption systems.

Features

• Hydrogen Purity up to 99.9999%

• Wide variety of feed gases

• Advanced adsorbents

• Patented Technology

• Compact and skid-mounted

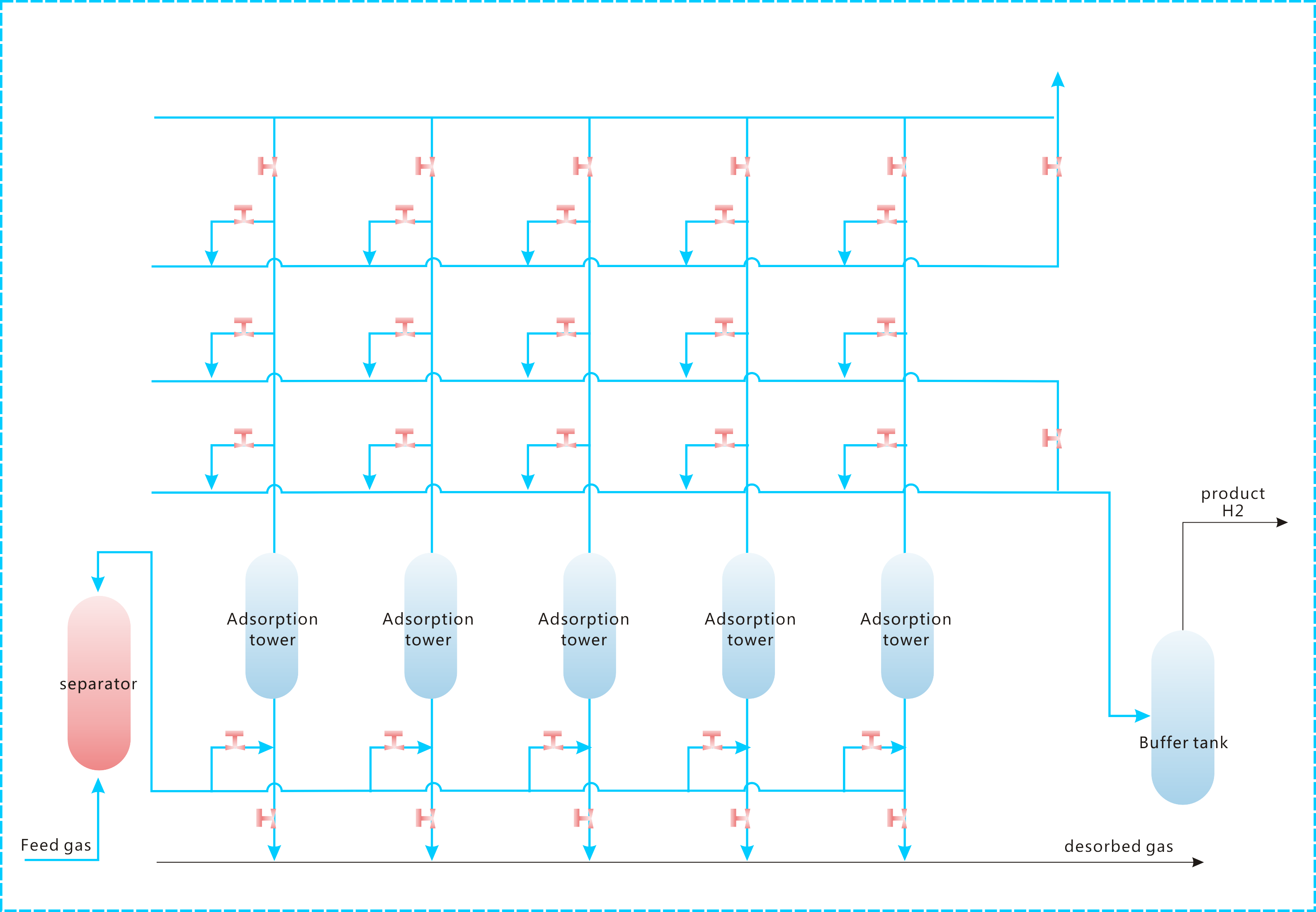

Technical Process

Multiple tower pressure swing adsorption technology is adopted. The working steps are divided into adsorption, depressurization, analysis and boosting. The adsorption tower is staggered in the working steps to form a closed-circuit cycle to ensure continuous input of raw materials and continuous output of products.

Main Technical Parameter

|

Plant size |

10~300000Nm3/h |

|

Purity |

99%~99.9995% (v/v) |

|

Pressure |

0.4~5.0MPa(G) |

Application

• Water-gas and semi-water gas

• Shift gas

• Pyrolysis gases of methanol cracking and ammonia cracking

• Off-gas of styrene, refinery reformed gas, refinery dry gas, purge gases of synthetic ammonia or methanol, and coke oven gas.

• Other sources of hydrogen-rich gases