Hydrogen Production by Ammonia Cracking

Ammonia Cracking

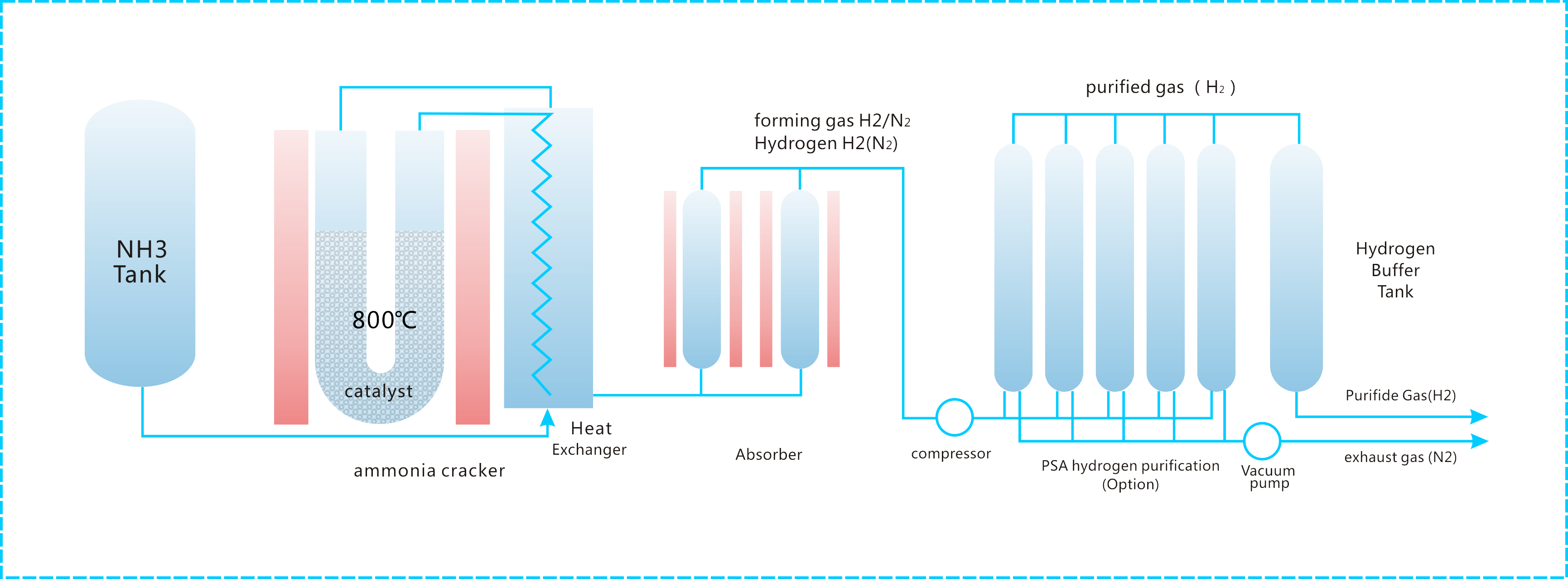

An ammonia cracker is used to generate the cracking gas which is consisted of hydrogen ant nitrogen at mole ratio of 3:1. The absorber cleans the forming gas from remaining ammonia and moisture. Then a PSA unit is applied to separate hydrogen from nitrogen as optional.

The NH3 is coming from bottles or from an ammonia tank. The ammonia gas is pre-heated in a heat exchanger and vaporizer and then cracked in the main furnace unit. The furnace is electrically heated.

The dissociation of ammonia gas NH3 takes place at a temperature of 800°C in the presence of a nickel-based catalyst in an electrically heated furnace.

2 NH₃ → N₂+ 3 H₂

The heat exchanger is used as an economizer: while the hot cracking gas is cooled down, the ammonia gas is preheated.

Gas Purifier

As an option and in order to reduce the dew point of the generated forming gas further, a special forming gas purifier is available. Using molecular sieve technology, the dew point of the generated gas can be reduced to -70°C. Two adsorber units are working in parallel. One is adsorbing moisture and un-cracked ammonia from the forming gas while the other one is heated for regeneration. Gas flow is switched regularly and automatically.

Hydrogen purification

PSA unit is used to remove nitrogen and therefore purify hydrogen, if it is required. This is based on a physical process that makes use of the different adsorption properties of different gases to separate hydrogen from nitrogen. Commonly several beds are deployed to realize the continues operation.

Cracking gas capacity: 10 ~ 250 Nm3/h

Hydrogen capacity: 5 ~ 150 Nm3/h