-

Coke Oven Gas Purification and Refinery Plant

Coke oven gas contains tar, naphthalene, benzene, inorganic sulfur, organic sulfur and other impurities. In order to make full use of coke oven gas, purify coke oven gas, reduce impurity content in coke oven gas, fuel emission can meet the requirements of environmental protection, and can be used as chemical production. The technology is mature and widely used in power plant and coal chemical i... -

Hydrogen Peroxide Refinery and Purification plant

The production of hydrogen peroxide (H2O2) by anthraquinone process is one of the most mature and popular production methods in the world. At present, there are three kinds of products with a mass fraction of 27.5%, 35.0%, and 50.0% in China market. -

Natural Gas to Methanol Refinery plant

The raw materials for methanol production can be natural gas, coke oven gas, coal, residual oil, naphtha, acetylene tail gas or other waste gas containing hydrogen and carbon monoxide. Since the 1950s, natural gas has gradually become the main raw material for methanol synthesis. At present, more than 90% of the plants in the world use natural gas as raw material. Because the process flow of me... -

Synthetic Ammonia Refinery Plant

Use natural gas, coke oven gas, acetylene tail gas or other sources containing rich hydrogen as raw materials to build small and medium-sized synthetic ammonia plants. It has the characteristics of short process flow, low investment, low production cost and low discharge of three wastes, and is a production and construction plant that can be vigorously promoted. -

Ally’s Specialty Catalysts and Adsorbents

ALLY has rich experience in the R&D, application and Quality inspection of catalysts and adsorbents used in the projects to ensure their engineering quality. ALLY has published 3 editions of “Industrial Adsorbent Application Manual”, the content covers the static and dynamic performance curves of hundreds of adsorbents from nearly 100 companies in the world.

Hydrogen Refueling Station

Hydrogen Refueling Station Long-run UPS System

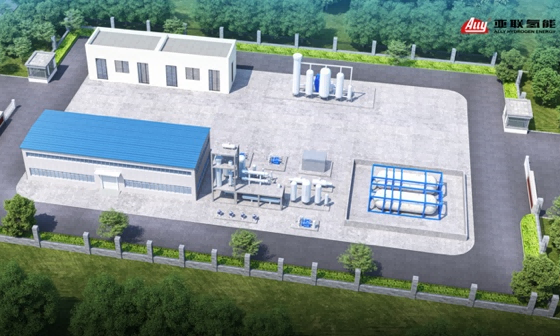

Long-run UPS System Integrated Chemical Plant

Integrated Chemical Plant Core Accessories

Core Accessories