As the global energy landscape undergoes a profound transformation, the China International Supply Chain Expo (CISCE) has established itself as a critical venue for highlighting the resilience and technological integration of the clean energy sector. The China One-Stop Integrated Hydrogen Production & Refueling Station Solution has emerged as a focal point for industry leaders seeking to streamline the transition to zero-emission logistics.

Current industry trends reflect a decisive move away from fragmented equipment supply toward unified, site-specific infrastructure. This shift is characterized by the co-location of generation and distribution systems, which effectively addresses the high costs and logistical complexities tradition ALLY associated with high-pressure gas transport.

Pioneering the Integrated Hydrogen Production and Refueling Station

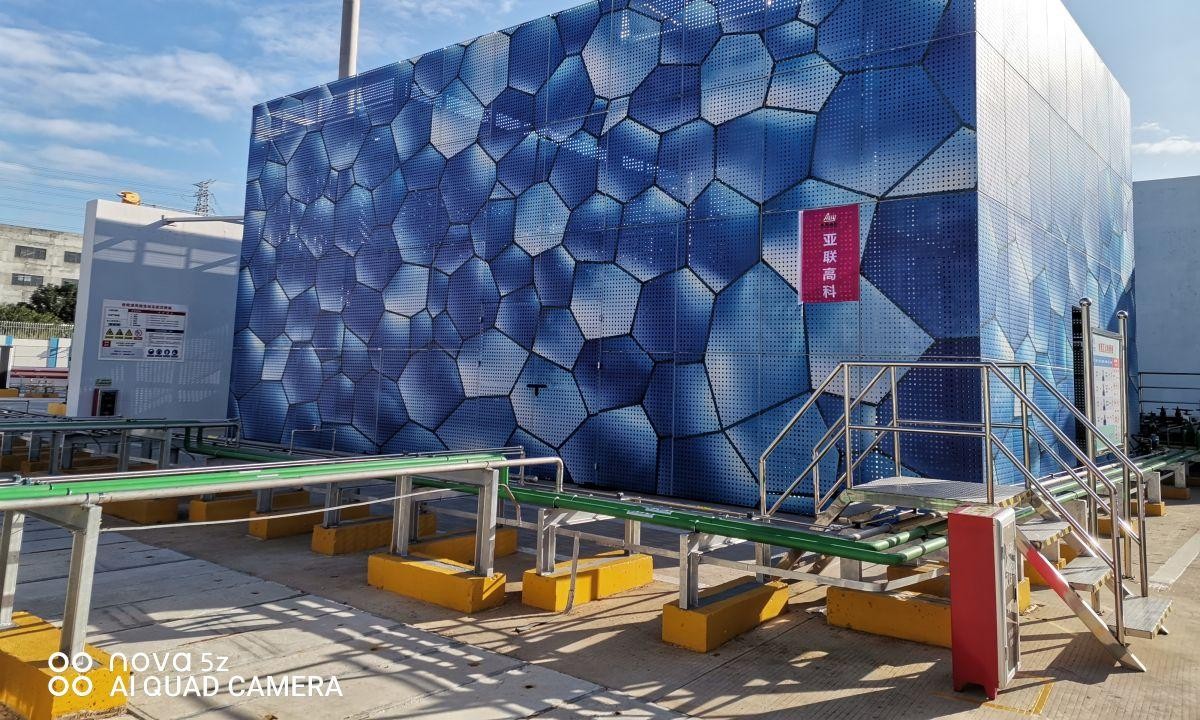

At the CISCE exhibition, ALLY Hydrogen Energy Co., Ltd.(formerly ALLY Hi-Tech) demonstrated how advanced engineering can bridge the gap between supply and demand. Founded in 2000 and headquartered in the Chengdu High-Tech Zone, ALLY Hydrogen Energy is a leading high-tech enterprise and a nation ALLY recognized “Little Giant” in innovation and specialization. By presenting a sophisticated integrated hydrogen production and refueling station, the company highlighted a pathway for industries to achieve energy independence. These systems allow for onsite hydrogen production—utilizing feedstocks such as methanol, natural gas, or water electrolysis—directly coupled with compression and dispensing units.

The current trajectory of the global market favors modular, skid-mounted solutions that offer a smaller physical footprint and faster deployment timelines. This is particularly relevant for urban logistics hubs and heavy-duty transport corridors where space is at a premium. ALLY’s participation in the expo underscores its role as a key contributor to national and international standards, ensuring that the next generation of energy infrastructure is built on a foundation of safety and interoperability.

Technical Excellence in Hydrogen Refueling Station Infrastructure

A central theme of ALLY’s showcase was the optimization of the hydrogen refueling station. Unlike standard facilities that act merely as distribution points, the integrated models focus on reducing the levelized cost of hydrogen through efficient onsite conversion. This is achieved by utilizing ALLY’s proprietary catalysts and purification technologies, which have earned the company numerous provincial and municipal technology awards.

The performance of a modern hydrogen refueling station is measured by its reliability under continuous load and its ability to serve various vehicle types. ALLY’s solutions support both 35 MPa and 70 MPa protocols, ensuring compatibility with a diverse fleet of fuel cell buses, trucks, and passenger cars. By eliminating the reliance on external supply chains, an integrated hydrogen production and refueling station provides a stable and predictable energy source, which is essential for the commercial viability of green transport networks.

Strategic Advantages in One-Stop Hydrogen Production

The competitive edge of ALLY Hydrogen Energy lies in its ability to master the entire chemical process of hydrogen production. With over two decades of experience, the company has refined the synthesis of hydrogen from various sources, including ammonia cracking and methanol reforming. This technical depth allows ALLY to offer a China One-Stop Integrated Hydrogen Production & Refueling Station Solution that is highly adaptable to the specific resource availability of a given region.

As a trusted partner for global giants such as Sinopec, PetroChina, Air Liquide, and the Linde Group, ALLY has proven that technical innovation must be paired with industrial-scale execution. The company’s focus on cutting-edge technologies for ammonia synthesis and methanol conversion ensures that their integrated hydrogen production and refueling station designs remain future-proof, capable of incorporating green hydrogen developments as renewable energy becomes more accessible.

A Comprehensive, Lifecycle-Based Service Model

One of the most significant highlights at CISCE was ALLY’s presentation of its “One-Stop” service ecosystem. The company moves beyond simple equipment manufacturing to provide a holistic support structure that ensures long-term project success. This comprehensive service framework is divided into several specialized stages:

ü Customized Design and Consulting: ALLY provides professional engineering design services that begin with a deep analysis of the client’s needs. This includes site selection, feasibility studies, and the creation of detailed process flow diagrams. By tailoring the hydrogen production method to the local environment, they ensure maximum efficiency from day one.

ü Precision Engineering and Construction: The company oversees the entire engineering phase, from procurement to onsite installation. Their expertise in high-pressure systems ensures that every hydrogen refueling station is built to withstand rigorous operational demands while adhering to strict international safety codes.

ü Specialized Technical Training: Recognizing that hydrogen technology requires specific expertise, ALLY offers extensive training programs for client personnel. These programs cover system theory, safety protocols, and emergency response, ensuring that the operators of an integrated hydrogen production and refueling station are fully equipped to manage the facility confidently.

ü Proactive After-Sales and Maintenance: The commitment to the client continues long after commissioning. ALLY provides a robust after-sales service that includes regular system health checks, rapid-response troubleshooting, and the supply of high-quality spare parts. This proactive approach minimizes downtime and extends the operational life of the hydrogen refueling station.

Empowering the Global Hydrogen Economy

The integration of advanced product engineering with a global service mindset has earned ALLY Hydrogen Energy a reputation for excellence. Partnerships with international entities like BP, Iwatani, and Taiyo Nippon Sanso highlight the global demand for reliable hydrogen production infrastructure. By delivering sustainable energy solutions that empower industries, ALLY is helping to build the “Clean Energy Chain” that was a central focus of the expo.

The transition to a hydrogen-based economy requires more than just hardware; it requires a partner capable of navigating the complexities of production, storage, and distribution. Through its integrated hydrogen production and refueling station solutions, ALLY Hydrogen Energy provides a turnkey pathway for decarbonization. As the company continues to drive technological breakthroughs, it remains dedicated to quality, innovation, and the delivery of a truly one-stop experience for the global market.

For more information on the latest innovations in hydrogen technology and comprehensive service solutions, please visit the official website: https://www.ally-hydrogen.com/.

Post time: Jan-16-2026

Hydrogen Refueling Station

Hydrogen Refueling Station Long-run UPS System

Long-run UPS System Integrated Chemical Plant

Integrated Chemical Plant Core Accessories

Core Accessories