In the sprawling industrial landscapes of northern China, the towering silhouettes of coking plants have long been symbols of economic production, yet they also carry the weight of environmental challenges. As night falls over a typical steel-manufacturing hub, the orange glow of coke ovens reflects a historical paradox: the massive generation of Coke Oven Gas (COG) as a byproduct. Historically, much of this gas was either flared, leading to significant carbon emissions, or used inefficiently as low-grade fuel.

Today, the narrative is shifting. The global urgency for energy transition has transformed this “industrial waste” into a strategic treasure trove for hydrogen production. At the heart of this transformation lies the Future Leading COG Purification Technology in China, a critical innovation that bridges the gap between traditional heavy industry and a zero-carbon future. By extracting high-purity hydrogen from complex gas mixtures, this technology addresses the critical industry pain point of resource wastage while providing a stable, localized fuel source for the emerging hydrogen economy, particularly in the steel and chemical sectors.

The Global Shift Toward Industrial Decarbonization and Hydrogen Integration

The global industrial sector is currently at a crossroads, navigating the complex transition from fossil-fuel dependency to sustainable energy systems. International climate agreements have catalyzed a worldwide movement toward decarbonization, with a particular focus on “hard-to-abate” sectors such as steel manufacturing, heavy-duty transportation, and chemical processing. In this context, hydrogen has emerged as the ultimate energy carrier. Europe and North America have made significant strides in green hydrogen, yet the immediate challenge remains the cost and scale of production.

China, as the world’s largest producer of both steel and coke, occupies a unique position in this global trajectory. The Chinese government’s “Dual Carbon” goals—peaking carbon emissions by 2030 and achieving carbon neutrality by 2060—have placed immense pressure on traditional industries to innovate. The industry’s primary struggle is not just reducing emissions, but doing so in a way that is economically viable. COG purification offers a pragmatic and high-impact solution. By refining the hydrogen-rich gas already generated during the coking process, industries can significantly lower their carbon footprint without waiting for the full-scale infrastructure of electrolysis to mature. This domestic focus aligns with international efforts to maximize resource efficiency and represents a cornerstone of China’s strategic energy security.

Core Advantages of COG Purification in the Modern Energy Landscape

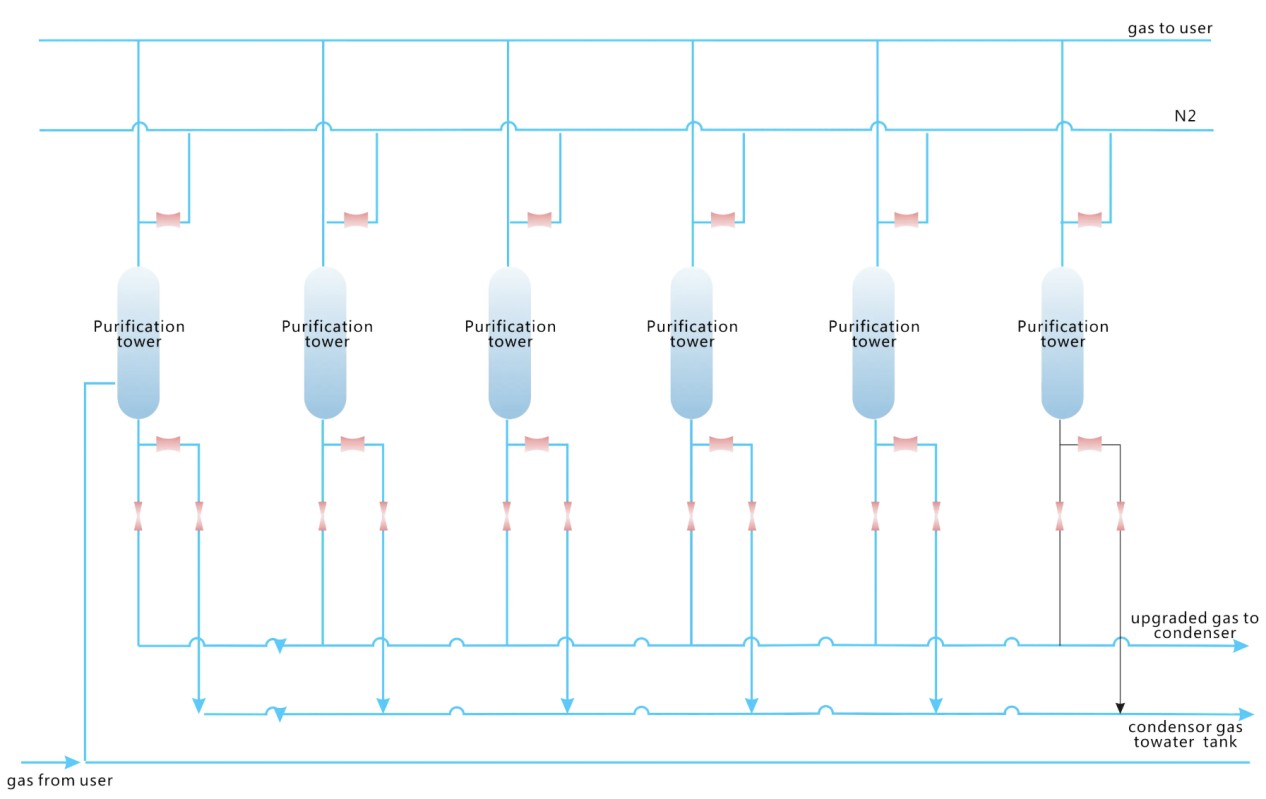

The process of turning raw coke oven gas into fuel-cell-grade hydrogen is technically demanding, requiring the removal of complex impurities such as tar, naphthalene, ammonia, and organic sulfur. The evolution of cog purification has moved toward higher efficiency and lower energy consumption. Modern systems now utilize advanced Pressure Swing Adsorption (PSA) technology, which allows for the selective separation of hydrogen at varying pressures. This specific cog purification technology in China has been refined to achieve purity levels exceeding 99.999%, meeting the stringent requirements of the hydrogen fuel cell vehicle (HCV) industry.

One of the standout features of the latest cog purification systems is their adaptability to fluctuating feed gas compositions. Industrial processes are rarely static; the quality of raw COG can vary based on coal types and oven temperatures. Advanced purification units now integrate intelligent control systems that monitor gas inflow in real-time, adjusting the adsorption cycles to maintain consistent output quality. Furthermore, the integration of multi-stage purification—incorporating pre-treatment, fine desulfurization, and final PSA stages—ensures that the catalyst and adsorbent life is maximized, reducing the total cost of ownership for industrial operators. This technical maturity in cog purification is what enables large-scale steel mills to transition into energy hubs, providing clean hydrogen for their own logistics fleets or for regional energy markets.

Strategic Analysis: Integrating Technology for Deep Decarbonization

Decarbonization is not a single-product solution but a holistic strategic undertaking. To truly impact the industrial landscape, cog purification must be viewed as part of a broader ecosystem of energy management. This involves not only the extraction of hydrogen but also its compression, storage, and eventual application. A comprehensive approach to industrial service includes the entire lifecycle of the project—from initial engineering design and manufacturing to commissioning and long-term technical support. By offering a full suite of hydrogen solutions, including water electrolysis and methanol-to-hydrogen conversion alongside cog purification, technology providers can help enterprises tailor their energy mix based on available local resources.

Successful industrial case studies across China demonstrate the viability of this integrated strategy. For instance, large-scale chemical groups have successfully deployed purification units that process hundreds of thousands of cubic meters of gas per hour, providing the raw material for ammonia synthesis or high-purity hydrogen for electronics manufacturing. These projects prove that cog purification is not merely an environmental compliance measure but a value-added industrial process. When combined with professional EPC (Engineering, Procurement, and Construction) services and modular skid-mounted designs, these technologies can be deployed rapidly, allowing companies to meet their sustainability targets within tight regulatory windows.

Leading the Path Toward a Sustainable Hydrogen Future

The journey toward a hydrogen-based economy requires a blend of deep industry experience and cutting-edge research. Ally Hydrogen Energy, a national high-tech enterprise based in the Chengdu High-Tech Zone, has spent 25 years at the forefront of this movement. Formerly known as Ally Hi-Tech, the company has evolved into a leading force in China’s hydrogen production industry, focusing on the research, development, and market promotion of advanced energy solutions. With a long history of serving international and domestic giants such as Sinopec, PetroChina, Air Liquide, and Linde, the company has established itself as a qualified supplier for first-class global corporations.

By focusing on the practical application of technology, Ally has extended its reach from core purification to the entire hydrogen value chain. Their commitment to quality and service has fostered long-term partnerships across the globe, including collaborations with Plug Power in the United States and Iwatani in Japan. As the world moves closer to its carbon neutrality goals, the role of specialized providers in delivering robust, efficient, and scalable cog purification technology in China becomes ever more vital. Through strategic analysis and technological excellence, the transition from traditional industrial byproducts to clean energy is not just a possibility—it is an unfolding reality.

For more information on ALLY’s hydrogen solutions and services, please visit: https://www.ally-hydrogen.com/

Post time: Feb-05-2026

Hydrogen Refueling Station

Hydrogen Refueling Station Long-run UPS System

Long-run UPS System Integrated Chemical Plant

Integrated Chemical Plant Core Accessories

Core Accessories